Canned meat production line

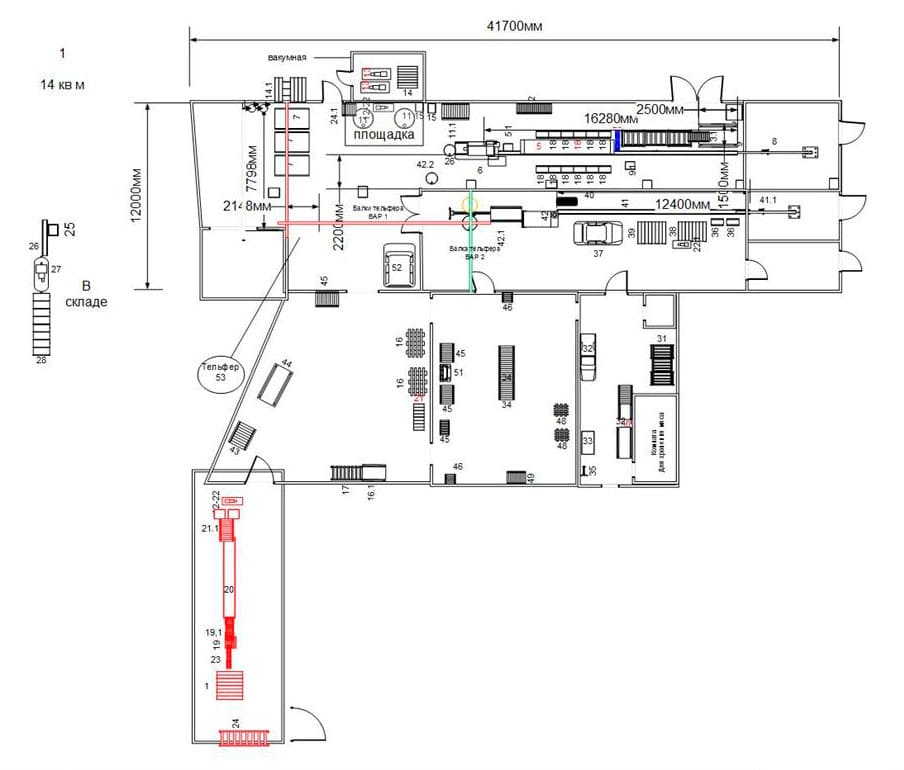

General view of the line and layout plan

Equipment Specifications

No. 1 Carts for moving the product

Overall dimensions 680*580*850 mm

No. 2. Tables for trimming

Overall dimensions 1500*600*850

No. 3 Spinning top lift No. 9 Loader

No. 1 Carts for moving the product

Overall dimensions 680*580*850 mm

No. 2. Tables for trimming

Overall dimensions 1500*600*850

No. 3 Spinning top lift No. 9 Loader

Load capacity, kg, no more : 300

Cycle duration, min : 035

Installed power, kW, no more : 1.5

Overall dimensions, mm :

Length : 755

Width : 1355

Height : 3080

Unloading height, mm, no more : 2000

Weight, kg : 285

Cycle duration, min : 035

Installed power, kW, no more : 1.5

Overall dimensions, mm :

Length : 755

Width : 1355

Height : 3080

Unloading height, mm, no more : 2000

Weight, kg : 285

No. 4. Top 500 kg/h

Loading bowl capacity, m3, no more : 0.07

Nominal lattice size, mm : 80

Height, mm :

- loading of raw materials : 1100+/-50

- unloading of the crushed product : 700+/-50

Installed power of the electric motor, kW, no more : 7.5

Overall dimensions, mm, no more :

- length : 720

- width : 650

- height : 850

Weight, kg, no more : 150

Productivity, kg / h, (when grinding beef of the 1st grade in pieces weighing up to 1.0 kg, pre-trimmed to a connective tissue content in it of not more than 10% of the total mass of meat through an outlet grate with a hole diameter of 3 mm) no more : 3000

Nominal lattice size, mm : 80

Height, mm :

- loading of raw materials : 1100+/-50

- unloading of the crushed product : 700+/-50

Installed power of the electric motor, kW, no more : 7.5

Overall dimensions, mm, no more :

- length : 720

- width : 650

- height : 850

Weight, kg, no more : 150

Productivity, kg / h, (when grinding beef of the 1st grade in pieces weighing up to 1.0 kg, pre-trimmed to a connective tissue content in it of not more than 10% of the total mass of meat through an outlet grate with a hole diameter of 3 mm) no more : 3000

4.1 Meat cutter

№5 Meat mixer

Geometric capacity of the trough, m3: 0.335

Cycle duration, min. : 3.5 ... 8

Total installed power, kW: 7.0

including:

- drive of kneading augers: 5.5

- loading mechanism drive: 1.5

Consumed electricity, kWh, not more than: 4.1

Specific electricity consumption, Wh/kg/h, max: 1.28

Overall dimensions of the machine, mm, not more than:

- length : 1650

- width : 965

- height : 1375

Occupied area, m2, not more than: 3.08

Capacity per unit of occupied area, m3.m-2: 0.108

Weight, kg, max: 580

Cycle duration, min. : 3.5 ... 8

Total installed power, kW: 7.0

including:

- drive of kneading augers: 5.5

- loading mechanism drive: 1.5

Consumed electricity, kWh, not more than: 4.1

Specific electricity consumption, Wh/kg/h, max: 1.28

Overall dimensions of the machine, mm, not more than:

- length : 1650

- width : 965

- height : 1375

Occupied area, m2, not more than: 3.08

Capacity per unit of occupied area, m3.m-2: 0.108

Weight, kg, max: 580

№6 Machine for filling cans with meat

Productivity technical, piece/h:

for cans №№ 3,4,8,9,43

GOST 5981-82, No. 12.13,

for cans №№ 3,4,8,9,43

GOST 5981-82, No. 12.13,

GOST 5981-82: up to 7200

for glass containers: up to 4680

Dose of meat, kg, no more: 1

Dosing accuracy, %: 3

Installed power, kW. : 5.2

Occupied area, m2: 4.49

Overall dimensions, mm: 3175x1415x1655

Weight, kg: 2300

for glass containers: up to 4680

Dose of meat, kg, no more: 1

Dosing accuracy, %: 3

Installed power, kW. : 5.2

Occupied area, m2: 4.49

Overall dimensions, mm: 3175x1415x1655

Weight, kg: 2300

It is used at meat-packing enterprises in canned meat production lines.

No. 6.2 Filler for pates

6.3. Filler for cereals

№7

Productivity : up to 4000 cans/hour

Overall dimensions: 350x3100x450

Steam consumption : 25 kg/h

Water consumption : 300 liters/hour

Designed for one size can

Overall dimensions: 350x3100x450

Steam consumption : 25 kg/h

Water consumption : 300 liters/hour

Designed for one size can

No. 8 Plate conveyor

Stainless version

SEW EURODRIVE constant speed drive

Tape Width: 86.2mm

No. 11 Seaming machine for cans with semi-automatic stacker

SEW EURODRIVE constant speed drive

Tape Width: 86.2mm

No. 11 Seaming machine for cans with semi-automatic stacker

Height : 2060 mm

Width : 1060 mm

Length : 2350 mm

Electrical power : 2.2 kW

Weight : 1650 kg

tin can : 3,5,8,12

Capacity : max 125 cans/min

Width : 1060 mm

Length : 2350 mm

Electrical power : 2.2 kW

Weight : 1650 kg

tin can : 3,5,8,12

Capacity : max 125 cans/min

No. 12 Washing filled cans after seaming

It is possible to install directly behind the seaming, then the can will move along the machine due to the pushing force of the seaming machine.

Stacking cans in baskets by hand.

Stacking cans in baskets by hand.

No. 12.1 Washing and drying of filled cans after the autoclave.

№14

Capacity : 1620 RMS 0.5

Dimensions : 2900x2065xh2400mm

Weight : 2450 Kg

Pump type and power : CALPEDA 7.5 kW

Heat exchanger : ALFA LAVAL

PLC : LG

Electronics and recording device : SİEMENS / ABB / TELEMEKANİK / LG

Cranes : SAMSON / TERMO / AYVAZ /

Cooling water consumption : 2 to 4 m3

Steam consumption : 500 to 1000 kg/h

Dimensions : 2900x2065xh2400mm

Weight : 2450 Kg

Pump type and power : CALPEDA 7.5 kW

Heat exchanger : ALFA LAVAL

PLC : LG

Electronics and recording device : SİEMENS / ABB / TELEMEKANİK / LG

Cranes : SAMSON / TERMO / AYVAZ /

Cooling water consumption : 2 to 4 m3

Steam consumption : 500 to 1000 kg/h

№ 14.1

Dimensions : 1350*2200*2750 mm

Inner diameter : 1000 mm

Working overpressure: 0.35 MPa

Internal volume: 1570 liters

Number of loaded baskets : 2

Inner diameter : 1000 mm

Working overpressure: 0.35 MPa

Internal volume: 1570 liters

Number of loaded baskets : 2

№ 14.2

| Number of jars (0.5 l glass jars) | 105 | 240 | 300 |

| Useful chamber volume, l | 180 | 423 | 490 |

| Power of heating elements, kW | 27 | 63 | 72 |

| Voltage, V | 380 | 380 | 380 |

| Sterilization temperature, °C (max) | 140 | 140 | 140 |

| Working pressure in the chamber, MPa | 0,4 | 0,4 | 0,4 |

| Overall dimensions, mm L*W*H | 950*1000*1560//1700*1400*1650//1700*1400*1750 | ||

| Weight, kg | 300 | 780 | 840 |

№16 Labeling with a marker

Productivity technical, piece/hour

Semi-automatic mode, not less than: 5600

Installed power, kW, no more: 1.5

Length : 1900

Width : 800

Height : 1200

Weight, kg: 260