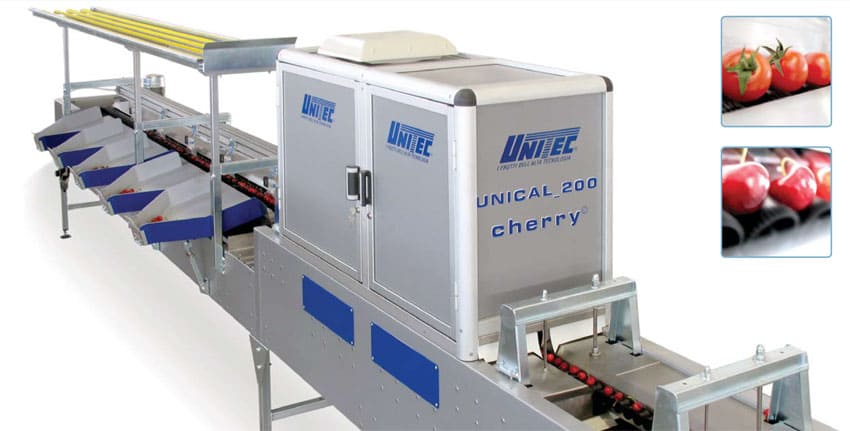

UNICAL_200 cherry mono© - Electronic sorter with high production for small fruits and sorting by size, color and defects

TECHNOLOGY: The electronic sorter is designed for sorting and sorting small fruits (12\40mm) such as cherries, cherry tomatoes, etc. A system with a roller conveyor ”INTELL-A-VEYOR” is used with sorting by optical size, color, shape, internal and external defects.

ACCURATE: complete protection of the integrity of the product is guaranteed by a pneumatic unloading system that allows the production of fruit up to 30 sectors / sec., with an air flow with an intensity proportional to the size.

PROFITABILITY: 30 to 50% reduction in costs (relative to a manual sorting strip), the possibility of using unskilled labor and an increase in production and product quality standards.

COST EFFICIENCY: Low additional costs thanks to a simple and functional design, easy to manage electrical equipment and high performance software of the latest generation.

ACCURATE: complete protection of the integrity of the product is guaranteed by a pneumatic unloading system that allows the production of fruit up to 30 sectors / sec., with an air flow with an intensity proportional to the size.

PROFITABILITY: 30 to 50% reduction in costs (relative to a manual sorting strip), the possibility of using unskilled labor and an increase in production and product quality standards.

COST EFFICIENCY: Low additional costs thanks to a simple and functional design, easy to manage electrical equipment and high performance software of the latest generation.

SPECIFICATIONS

Size classes: unlimited.

Color classes: unlimited.

Color choice: average and/or percentage, with the possibility of combining both.

Accuracy: high precision optical size (< 0.25 mm)

Power: up to 108.000 sectors/hour.

Number of bands: 1

Size classes: unlimited.

Color classes: unlimited.

Color choice: average and/or percentage, with the possibility of combining both.

Accuracy: high precision optical size (< 0.25 mm)

Power: up to 108.000 sectors/hour.

Number of bands: 1

MODELS

UNICAL_200 cherry mono O: Sort by size.

UNICAL_200 cherry mono OC: Sort by size and color.

UNICAL_200 cherry mono OCD: Sort by size, color and defects.

UNICAL_200 cherry mono©

CAMPIONATRICE

UNICAL_200 cherry mono O: Sort by size.

UNICAL_200 cherry mono OC: Sort by size and color.

UNICAL_200 cherry mono OCD: Sort by size, color and defects.

UNICAL_200 cherry mono©

CAMPIONATRICE

UNICAL_200 cherry mono© used as sampling provides real-time data on samples processed for each batch (ie: size percentages, colors, waste) to evaluate the quality and characteristics of the product. Due to operational software interdependencies, sample reports can be printed and customized for each manufacturer.

UNICAL_200 cherry mono© significantly reduces operating costs, it performs a large number of samples, ensuring the honesty of the manufacturer in the selection of the product.

UNICAL_200 cherry mono© significantly reduces operating costs, it performs a large number of samples, ensuring the honesty of the manufacturer in the selection of the product.